Silicone Heater

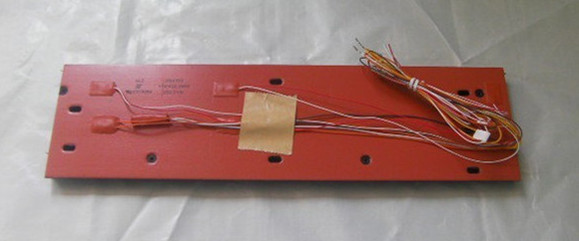

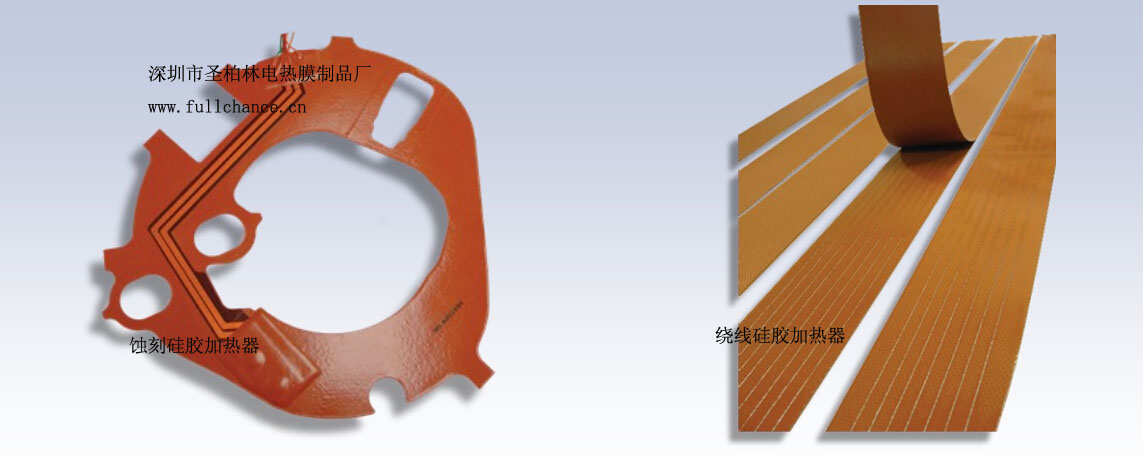

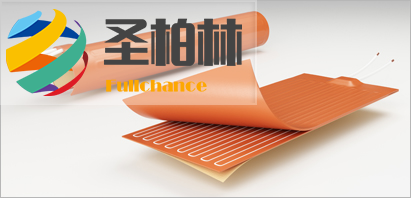

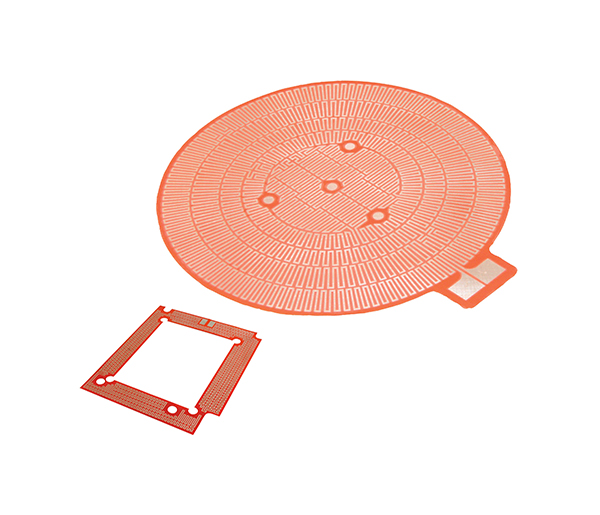

Our line of silicone heating mats can be your ideal heating solution. Depending on your application these heaters can us Etched Foil, Kapton or resistance wires laminated between sheets of silicone. The wire wound mats are ideal for prototyping or long term solutions for surface heating. Types of HeatersThere are different ways and materials to construct a silicone heater with each their own advantage. Etched FoilThe so called "foil tracks" are chemically etched and then laminated between thin sheets of silicone. This tracks are computer designed which make te possiblities basisly endless. The "tracks" are not suitable to be used in situation where they are bent back-n-forth often. Due to the wide foil tracks, rapid heat up properties and the precise temperature control abbilities these heaters give a very even and precise form of heating. The application method of this heater can be straps or buckles but also adhered by using PSA adhesive. This style of silicone heater is suitable for both high and low volume production. Wire Wound construction

The wire wound construction in mostly used for low volume heaters. The results of a wire wound construction are the same compared with the etched foil construction. Wire wound construction can be used for prototyping or testing, or when you only need one heater. These heaters are robust and flexible and available in any shape or size. Because of the flexibility these heaters can be used in many applications indoors else well as outdoors. Fullchance has a lot of experience with these heaters and are able to make any kind of heater that will meet your needs. For more information please contact us. Preformed Heaters ConstructionFor all cylindrical items such as pipes, tubes etc. it is possible to use preformed heaters. For small diameters it can be easier to make a preformed heater, than using a silicone heater mat. For more information please contact us. Insulation

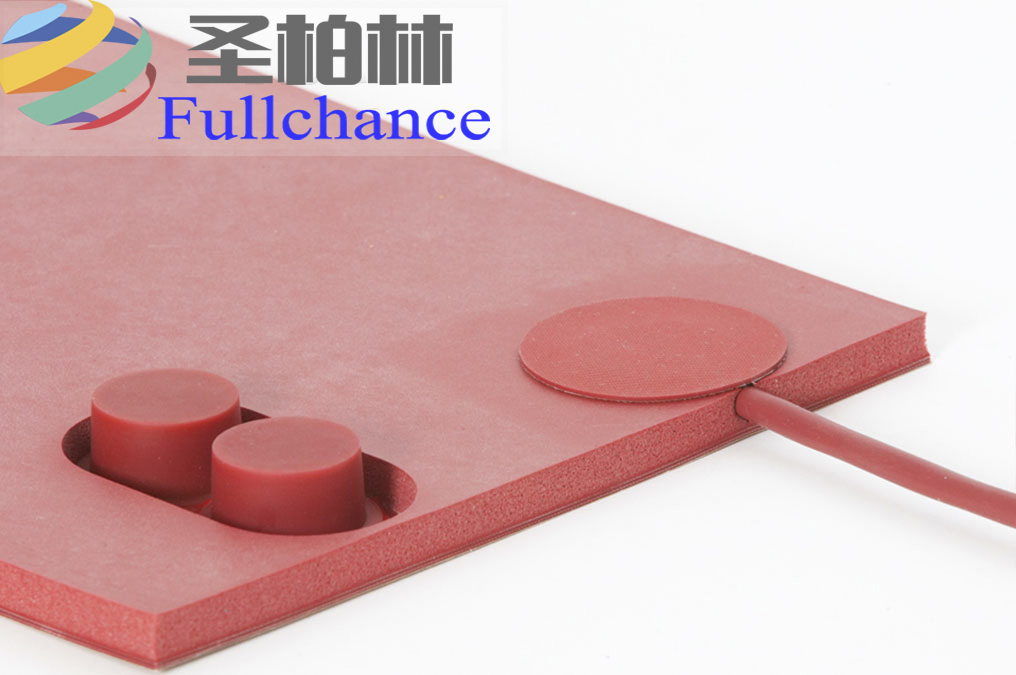

With some applications it can be wishfull to make the heater more efficient. This can be done by adding thick close-cell silicone foam to the heater. This optimizes the insulation value and thus the use of electric power.

B) Thermal Insulation To increase heater efficiency, silicone sponge rubber or EPDM insulation can be bonded to the top side of the heater. Typical thermal insulation thicknesses are 5mm, 8mm, 10mm.

C) Temperature Control and Thermal Management(Preset Built-in Thermostat, Adjustable Thermostat, Built-in temperature sensors(k,J thermocouples, RTD-PT100, digital controller) Thermostats, temperature sensors, digital temperature controller and thermal fuses can be fabricated as an integral part of the heaters. Pre-set Mechanical Thermostats: Snap action and creep action are two different types of pre-set Mechanical thermostats. Both are based on a bimetal expansion-contraction principle and are pre-set to a specific temperature non-adjustable. Typical applications are freeze protection, enclosure temperature and high limit protection.They provide a low cost means temperature control. The thermostat is normally built in by wiring directly into the heater and enclosed in a molded silicone rubber/fiberglass housing on the heater permanently. Electronic controller with sensor is suggested over the mechanical thermostat for precise temperature control applications. Adjustable Mechanical Thermostats: Adjustable Mechanical thermostats allow the user to set a specific temperature and attain a desired result. The thermostat is encapsulated in a silicone rubber overmold. Typical Adjustment Ranges Available are: 0~80 Deg C, 30~150 Deg C, 50~250 Deg C.  Buit-in Temperature Sensors: Thermocouples, RTDs, and thermistors can be located to monitor temperature of either the heat sink (part being heated) or the heater surface itself. For silicone heaters, temperature sensors are held in place with a protective patch or probe pocket of silicone rubber/fiberglass vulcanized to the heater body while for Kapton® heaters they are affixed to the surface with epoxy. Thermocouples: Almost any type thermocouple can be applied at almost anywhere on the heater surface. Type ”J” and "K" are most commonly employed. Resistance Temperature Devices: The RTD’s resistance changes in a very linear relationship with its temperature and is considered the most accurate and stable sensor. Thin film PT100 or PT1000 are commonly used. They can also be encased in probes. Thermistors: Thermistors are also resistive-based temperature sensors but as they do not respond in a linear style, they are only used in a limited temperature range or at a specific single temperature. Thermal Fuse: Thermal fuses are a one time over temperature protection device that can prevent dangerous temperatures in the event of a control device failure. Testing is suggested to select the location and temperature setting of the fuse to protect your product most effectively. Digital Temperature Controller: Recommended for applications where precise temperature control is desired. A complete control option, ready to be used with plug and sensor fitted. NO MORE tedious wiring before precise temperature is possible.

Profile of silicone rubber heater:

Silicone Rubber Heaters are available as wire wound or etched foil. Wire wound elements consist of the resistance wire wound on a fiberglass cord for support and stability. Etched foil heaters are made with a thin metal foil (.001”) as the resistance element. Wire wound is recommended and preferred for small to medium size quantities, medium to large sized heaters, and to produce prototypes to prove out the design parameters prior to entering into large volume production runs with etched foil.

ELEMENT CONSTRUCTION  Silicone Rubber heaters with wire-wound elements provide excellent physical strength capable of withstanding repeated flexing without compromising the life and performance of the heater. They are also very effective for manufacturing geometrically challenged shapes, including three dimensional ones. The wire-wound process is recommended and preferred for small to medium size quantities, medium to large size heaters, and to produce prototypes to prove out the design parameters prior to entering into large volume production runs when using etched foil.

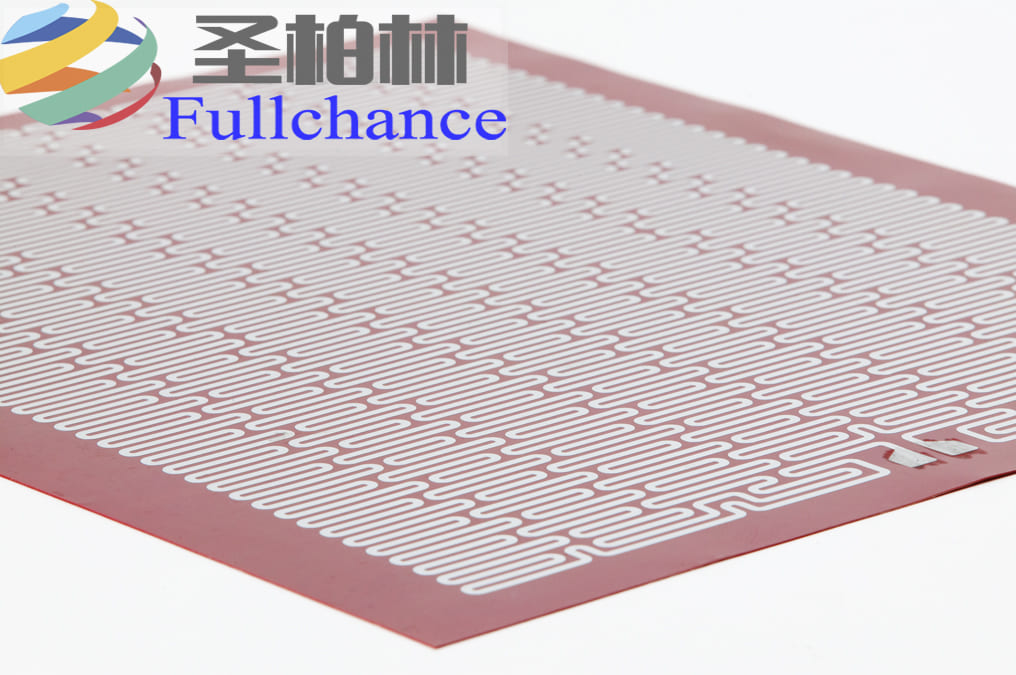

The wire-wound element process consists of resistance wire wound on a fiberglass cord for added support and flexibility. The wire-wound element is laid out in a special designed pattern to ensure uniform heat profile and to conform to the size and shape of the silicone rubber heater, avoiding holes and cutouts, or to concentrate the heat profile in a specific section(s) of the heater as the application dictates. Power lead wires or cord sets are attached to the heater windings with solder and firmly secured in place through a vulcanizing process, ensuring that the assembly becomes homogenous

|

|

|

|

|

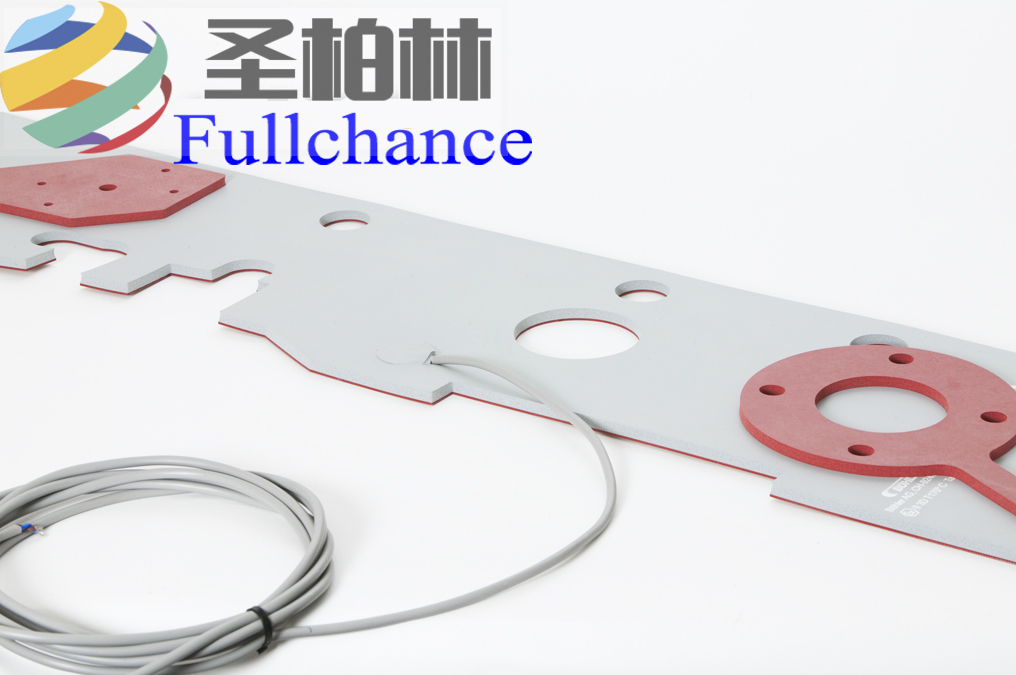

Lead Exit A

Exit together, centered on heater widthLead Exit B

Exit together, to one side of the heater widthLead Exit C

Exit together, to one side of the heater widthLead Exit D

Exit opposite ends, centered on the heater widthLead Exit E

Exit opposite ends, to one side of the heater widthLead Exit F

Exit together, centered on heater lengthLead Exit G

Exit together, to one side of the heater lengthLead Exit H

Exit together, to one side of the heater lengthLead Exit J

Exit opposite ends, on the same side of the heater lengthLead Exit K

Exit together from the center of the heater surface

Lead Exit L

Exit together the edge of a round heaterLead Exit M

Exit together at a corner

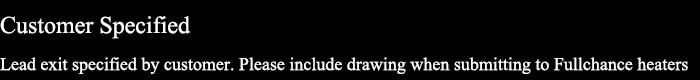

ELECTRICAL TERMINATIONS

Teflon Coated Lead Wire

Fullchance's standard leads are 10" long, Teflon® insulated, flexible, stranded, plated copper wire. Stripped: 1/4"

- 300V 200°C

- 600V 200°CThe lead connections are insulated with vulcanized silicone rubber, which also acts as a strain relief.

HPN Cord

For portable heaters, a two-conductor neoprene cordset can be vulcanized to the heater in any desired length.HPN Cord and Plug

A two-conductor neoprene cord and plug set can be vulcanized to the heater.

Standard Length: 6 ft. (1.83 M), 7 ft. (2.13M), or custom length as specified.

Supplied with standard straight blade ungrounded plug, or grounded plug. 120Vac only.

- 2-Pole 2 wire non-grounding (NEMA 1-15P)

- 2-Pole 3 wire grounding (NEMA 5-15P)

SJO Cord

For industrial applications, SJO heavy duty power cords can be attached to the heaters in any desired length.SJO Cord and Plug

SJO heavy duty power cord and plug set can be attached to the heaters. Standard Length: 6 ft. (1.83 M), or custom length as specified. Supplied with standard straight blade ungrounded plug, or grounded plug. 120Vac only. (For 240Vac see page 15-15 for optional plugs)

- 2-Pole 2 wire non-grounding (NEMA 1-15P)

- 2-Pole 3 wire grounding (NEMA 5-1

Silicone Rubber Leads

Ensures a moisture seal on the heater. Due to the similarity in material, the heater will fuse to the leads during the vulcanization process. Silicone rubber leads are more flexible, but are not as abrasion resistant as Teflon® leads.TERMINATION OPTIONS

Crimp connectors

Crimp Connectors: insulated or non-insulated

- Ring Terminal

- Spade Terminal

- 1/4" Female Straight Disconnect

- 1/4" Female Right-Angle Disconnect

- Miniature Connectors: example – Molex

Plugs

- Standard 120 or 240 Vac – straight blade

- Twist locking plugs, 120 to 480 Vac

- Specify NEMA or manufacturer's part number

-

Built-Up Molded Lead Exit

Used to encase lead exit and optional snap action thermostat.

Shown with SJO cord rated -50°C to 105°C.

![]()

Sleeving

Various materials can be put over Teflon® or Silicone Rubber leads to provide mechanical or abrasion protection. The leads exit the heater as a single unit.

- Silicone Rubber/Fiberglass Sleeving (356°F/180°C)

- Heat Shrink SleevingMOUNTING METHODS

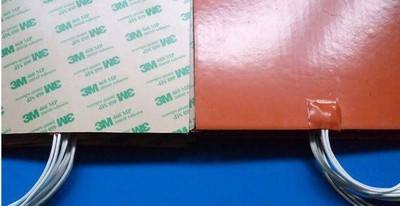

PSA (and PSA Plus)

For ease of attachment, specify PSA. Installation is simple: just peel off the protective liner and apply. It will adhere to most clean smooth surfaces. Care must be taken when installing to attain a smooth, consistent, uniform bond to achieve maximum results.

Maximum Temperature:

Continuous – 300°F (149°C)

Intermittent – 500°F (260°C)

Recommended Watt Density:

Under 5 W/in2 (0.78 W/cm2)

PSA Plus

A layer of aluminum foil is vulcanized to the back of the heater for added

heat dissipation prior to the application of PSA.

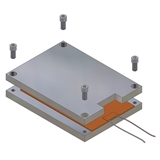

Factory Vulcanizing

Flexible heaters can be factory vulcanized to bare or anodized aluminum, Stainless Steel, Marble, or other hard surfaces for permanent attachment and excellent heat transfer.

The uncured silicone rubber heater is placed on the metal part and placed in the vacuum oven where the heater vulcanizes and adheres to the part in one operation. This procedure forms an extremely strong permanent bond with most metals due to the fact that the silicone rubber flows into and fills the micro structure in the surface of the metal. The metal part can be manufactured by Fullchance or supplied by the customer. Consult Fullchance for other materials including granite.

Magnetic Mounting

A flexible magnetic material can be attached to the back of a silicone rubber flexible heater. Will adhere to many varieties of steel. Ideal for those situations were you need to "Slap On" some heat! Specify when requesting a quote.Maximum Temperature: 200°F / 93°C

Maximum Watt Density: 1 W/in2 (0.16 W/cm2)

Maximum Width: 24" (610 mm)

Field Applied Adhesive

For a field applied permanent bond, a room temperature and ambient humidity curing silicone rubber adhesive is recommended. Fullchance offers two types that will retain physical and electrical properties up to 500°F (260°C).

When using RTV adhesive, cover the heater completely with a thin layer of RTV, position the heater in place, and use a small roller to remove air bubbles, which could cause hot spots and lead to premature failure of the heater.

![]()

D-Rings and Straps

Mechanical fasteners are available for applications where flexible heaters must be detachable from cylindrical parts.

Velcro Straps

Mechanical fasteners are available for applications where flexible heaters must be detachable from cylindrical parts.Boot Hooks and Springs

Mechanical fasteners are available for applications where flexible heaters must be detachable from cylindrical parts.Boot Hooks and Lacing Cord

Mechanical fasteners are available for applications where flexible heaters must be detachable from cylindrical parts.Grommets and Lacing Cord

Mechanical fasteners are available for applications where flexible heaters must be detachable from cylindrical parts.

Heavy Duty Spring Clamps

Mechanical fasteners are available for applications where flexible heaters must be detachable from cylindrical parts.Snaps

Mechanical fasteners are available for applications where flexible heaters must be detachable from cylindrical parts.

Clamping

Flexible heaters may be applied by clamping or compression between two rigid materials. The plate surfaces must be ground reasonably smooth. Care must be taken not to damage the heater or pierce the insulation. Mill out an area or cutout in the top plate for the added thickness of the lead exit area.Recommended Maximum Pressure: 40 PSI

Outside Diameter Mounting

Mechanical fasteners are available for applicationsFullchance has developed the techniques necessary to permanently mount silicone rubber heaters to the outside diameters of pipes and medium size vessels. This technique is particularly useful for heated drums and air or gas heating.

Minimum Diameter: 0.5" (12.7 mm)

Maximum Diameter: 6" (152.4 mm)

Maximum Length: 20" (508.0 mm)

3-D Configurations

Dimensional silicone rubber heaters can be vulcanized to fit a shaped outline. This technique is particularly useful for wrapping Silicone Rubber heaters around pipes or small vessels. Custom tooling or special forms may be required.

SENSOR OPTIONS

Thermocouple

Fullchance can incorporate common Type J or K thermocouples almost anywhere on the heater surface. Other thermocouple types can also be used. Standard thermocouple temperature ranges apply. Specify when ordering. See Temperature Sensors for optional plugs.RTD's

The RTDs (2- or 3-wire) used are platinum thin film 100 ohm @ 100°C. The standard curve is 0.00385 TCR / DIN432760. Other common RTDs such as 1000 ohm can also be used. Specify when ordering.The RTD's resistance increases with a rise in temperature and is considered the most accurate and stable sensor.

Thermistors

Thermistors are also a resistive-based temperature sensor. They do not generally respond in a linear style and are used in a limited temperature range or at a specific single temperature.Small bead style thermistors can be mounted directly on the heater.

The thermistor's response is generally designed directly into the customer's electronic control system. Therefore if a thermistor is required, specify manufacturer, specific model number, type and specifications when requesting a quote. Consult Fullchance for more information.

No Temperature Sensor

A temperature sensor is not needed for this heater.

![]()

TEMPERATURE CONTROL OPTIONS

Snap Action Thermostat - Automatic Reset

Quick cutout on rise to temperature. The contacts will open on rise when the temperature increases to the snap point of the calibrated bimetal disc.

Setpoint (opens): available from 50 to 450°F in 10°F increments (most thermostats close 20 to 30°F below setpoint)

Electrical Ratings: 125 Vac, 15 Amp, 1875W, 250 Vac, 10 Amp, 2500W

Minimum Heater Width: 1.312"

![]()

Adjustable Thermostat

Adjustable thermostats allow the user to dial-in a specific temperature and attain a desired result. The thermostat is enclosed in a molded silicone rubber housing and permanently attached to the heater. The adjustment shaft extends through a pre-formed hole. A high temperature knob is included.

Amps: 12.5A @ 125V, 6.5 A @ 250V

Watts: 1500W @ 120V, 1560W @ 240V

Adjustment Ranges Available:

- 50 to 425°F (10 to 218°C)

- 90 to 140°F (32 to 60°C)

- 100 to 190°F (38 to 88°C)

- 70 to 190°F (21 to 88°C)

- 50 to 160°F (10 to 71°C)

- 70 to 140°F (21 to 60°C)

![]()

Snap Action High Limit Thermostat

A High Limit with a manual reset push button can also be designed in.Specify when requesting a quote.

NOTE: See page 13-83 for stock temperature ratings

Creep Action Thermostat

Sustained response, and a slow cutout at the trip point. The creep action thermostat has a slow make/slow break action around setpoint.Setpoint (opens): available in a limited selection from 50 to 300°F in 10°F increments. Consult Fullchance.

Electrical Ratings: 120 Vac, 12 Amp, 1440W, 240 Vac, 6 Amp, 1440W

Thermal Fusing

Thermal fuses / cutoffs are used as high limit protection devices to guard the object being heated from dangerous temperatures in the event of a primary control device failure. The thermal fuse can be mounted using various methods depending on other options. If the heater does not have a thermostat, the thermal fuse would be mounted under the lead exit patch. If used in conjunction with a thermostat, it could be mounted under the thermostat cover.ADDITIONAL OPTIONS

Internal Ground Screen Plane

Some applications may require the heater to be grounded. Due to the fact that the heater sheath is non-conductive, this can only be done artificially. A second layer of insulating material and a conductive grid can be added to the heater. A ground wire is attached to the grid.

A less expensive alternative for setting up a ground wire, especially for the required ground lead of a cordset, is to have a "flying ground lead" (6" long, green) exit the lead patch for attaching to the metal load surface, effectively grounding the process.

![]()

Dual Voltage/3-Phase

Due to the flexibility in circuit design for flexible heaters, heating circuits can be designed to accommodate dual voltage.

On dual voltage heaters, three leads, including a common in a different color, are provided for wiring the heater in series for the higher voltage and parallel for the lower voltage. 120/240 Vac or 240/480 Vac can be specified.

Three-phase circuits can also be designed for large high-current applications.

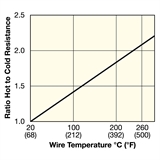

Self-Limiting/Self-Regulating

The alloy used for this heater's resistance wire has a high positive temperature coefficient of resistance that allows the heater to reduce power as temperature increases. This self-regulating feature is ideal for many low temperature applications. This feature can also be beneficial when a fast start-up time is required before the heater power levels off to normal

operating temperature.

See Chart for Ratio of Hot to Cold Resistance of the Heater wire at various wire temperatures.

![]()

Thermal Sponge Insulation / Thermal Conductive Sponge

To increase heater efficiency, silicone sponge rubber insulation can be bonded to the top side of the heater.

Available thicknesses are 1/16", 1/8", 1/4", 3/8" or 1/2".

Thermal Conductive Sponge can be use to transfer heat evenly to various surfaces. Available in 1/8" thickness.

![]()

Foil Backing

Aluminum foil can be added to the back of the heater to help dissipate the heat between element runs and eliminate hot spots. Due to the foil, higher watt densities and better temperature uniformity can be attained. The foil would be applied to the back of the heater, on the mounting surface.

Distrubted Wattage

In order to compensate for heating losses around the edges or mounting holes, the heating circuit can be designed in a distributed wattage pattern. More wattage can be added to the high loss areas to compensate for the higher losses.

Lead Exit Tab

An unheated lead exit tab can be added to the heater for a variety of reasons such as maintaining a rectangular heater with no cold sections or when used in a compression application to remove the lead exit area from between the plates. (Standard 2" x 2")

Multiple Zones

Multiple circuit areas can be zoned to compensate for various heating effects desired. In the picture above there are three zones with separate leads (A, B, and C).

customer service1

customer service1