|

|

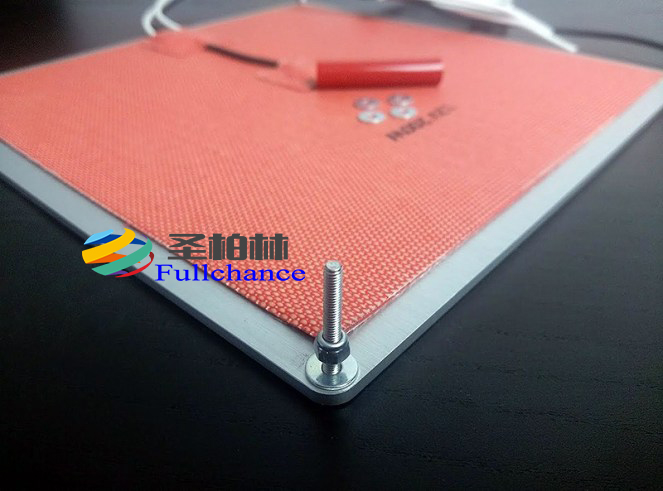

Now this bit is entirely personal preference, but I chose to put a washer at the base with a locking nut on top. On build plates with threaded holes this won’t matter as much, but it will secure the bolt in place and prevent movement that can otherwise affect the bed’s leveling.

To keep things simple, I grabbed a piece of cardboard and measure out the desired length with digital calipers. I then marked the two endpoints as a guide, and the silicone tubing was placed in between them to make the cuts. They don’t have to be perfect, but get them as close as possible and clean up the ends with a straight edge razor before installation (box cutter works great).

|

|

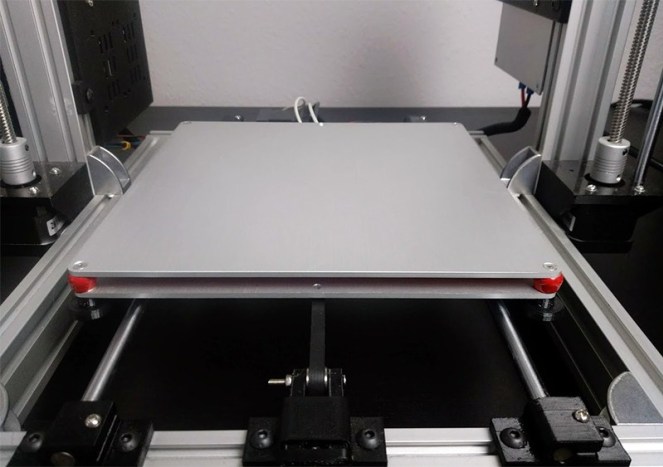

With the hardware installed, we can put the heated bed back on the 3D Printer and then start wiring it up. If you have spare M3 nuts on hand, you can thread one on the end of each screw to temporarily keep things in place, but otherwise just turn it over slowly and slide the screws in to the Y-carriage one at a time.

More details related information

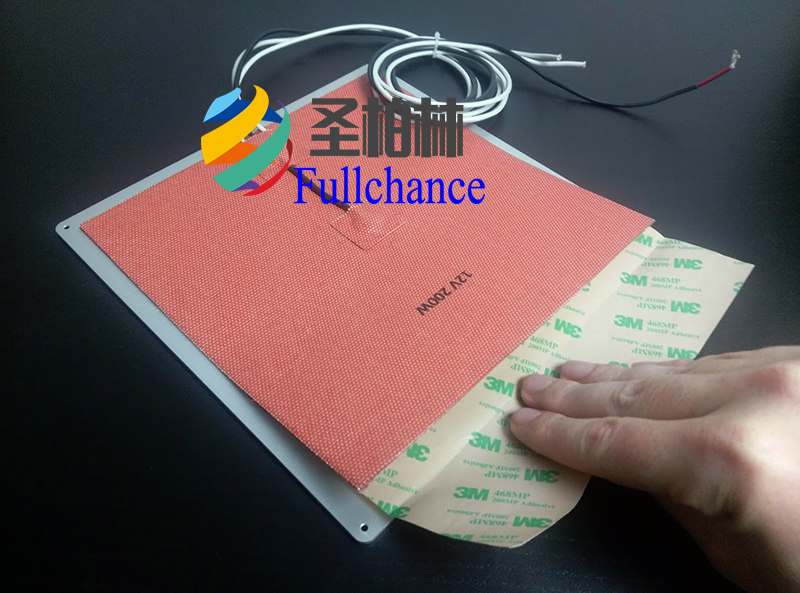

A layer of aluminum foil is vulcanized to the back of the heater for added

heat dissipation prior to the application of PSA.

Factory Vulcanizing

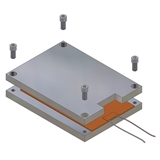

Flexible heaters can be factory vulcanized to bare or anodized aluminum, Stainless Steel, Marble, or other hard surfaces for permanent attachment and excellent heat transfer.

The uncured silicone rubber heater is placed on the metal part and placed in the vacuum oven where the heater vulcanizes and adheres to the part in one operation. This procedure forms an extremely strong permanent bond with most metals due to the fact that the silicone rubber flows into and fills the micro structure in the surface of the metal. The metal part can be manufactured by Fullchance or supplied by the customer. Consult Fullchance for other materials including granite.

Magnetic Mounting

A flexible magnetic material can be attached to the back of a silicone rubber flexible heater. Will adhere to many varieties of steel. Ideal for those situations were you need to "Slap On" some heat! Specify when requesting a quote.Maximum Temperature: 200°F / 93°C

Maximum Watt Density: 1 W/in2 (0.16 W/cm2)

Maximum Width: 24" (610 mm)

Field Applied Adhesive

For a field applied permanent bond, a room temperature and ambient humidity curing silicone rubber adhesive is recommended. Fullchance offers two types that will retain physical and electrical properties up to 500°F (260°C).

When using RTV adhesive, cover the heater completely with a thin layer of RTV, position the heater in place, and use a small roller to remove air bubbles, which could cause hot spots and lead to premature failure of the heater.

![]()

D-Rings and Straps

Mechanical fasteners are available for applications where flexible heaters must be detachable from cylindrical parts.

Velcro Straps

Mechanical fasteners are available for applications where flexible heaters must be detachable from cylindrical parts.Boot Hooks and Springs

Mechanical fasteners are available for applications where flexible heaters must be detachable from cylindrical parts.Boot Hooks and Lacing Cord

Mechanical fasteners are available for applications where flexible heaters must be detachable from cylindrical parts.Grommets and Lacing Cord

Mechanical fasteners are available for applications where flexible heaters must be detachable from cylindrical parts.

Heavy Duty Spring Clamps

Mechanical fasteners are available for applications where flexible heaters must be detachable from cylindrical parts.Snaps

Mechanical fasteners are available for applications where flexible heaters must be detachable from cylindrical parts.

Clamping

Flexible heaters may be applied by clamping or compression between two rigid materials. The plate surfaces must be ground reasonably smooth. Care must be taken not to damage the heater or pierce the insulation. Mill out an area or cutout in the top plate for the added thickness of the lead exit area.Recommended Maximum Pressure: 40 PSI

Outside Diameter Mounting

Mechanical fasteners are available for applicationsFullchance has developed the techniques necessary to permanently mount silicone rubber heaters to the outside diameters of pipes and medium size vessels. This technique is particularly useful for heated drums and air or gas heating.

Minimum Diameter: 0.5" (12.7 mm)

Maximum Diameter: 6" (152.4 mm)

Maximum Length: 20" (508.0 mm)

customer service1

customer service1