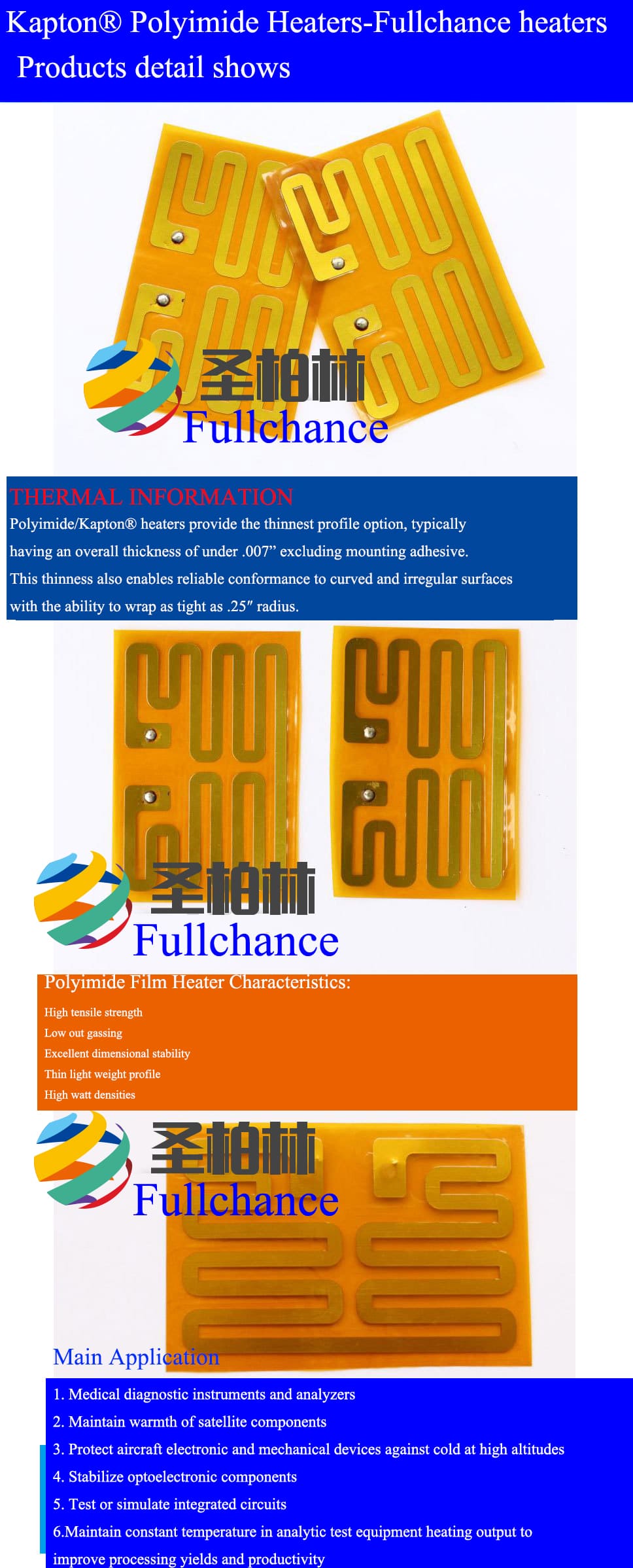

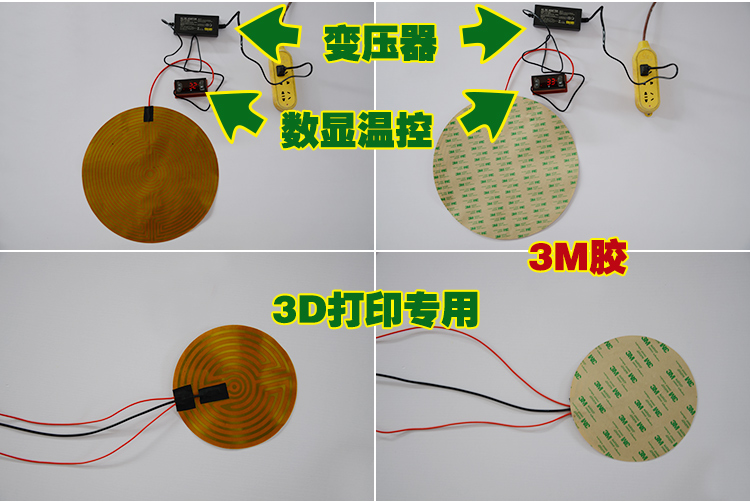

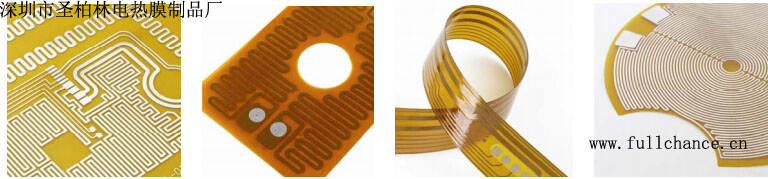

Kapton® Polyimide Heaters

Extremely thin and lightweight, polyimide heaters can quickly provide heat to where it is needed. Created by laminating an etched metallic foil element between layers of polyimide, Kapton heaters are exceptionally well suited for applications where the size and weight of the heater is a concern

![]()

Thin and Lightweight

Polyimide heaters can be designed to thicknesses of less than 0.01" (0.025 mm) and weigh less than a gram per square inch.

![]()

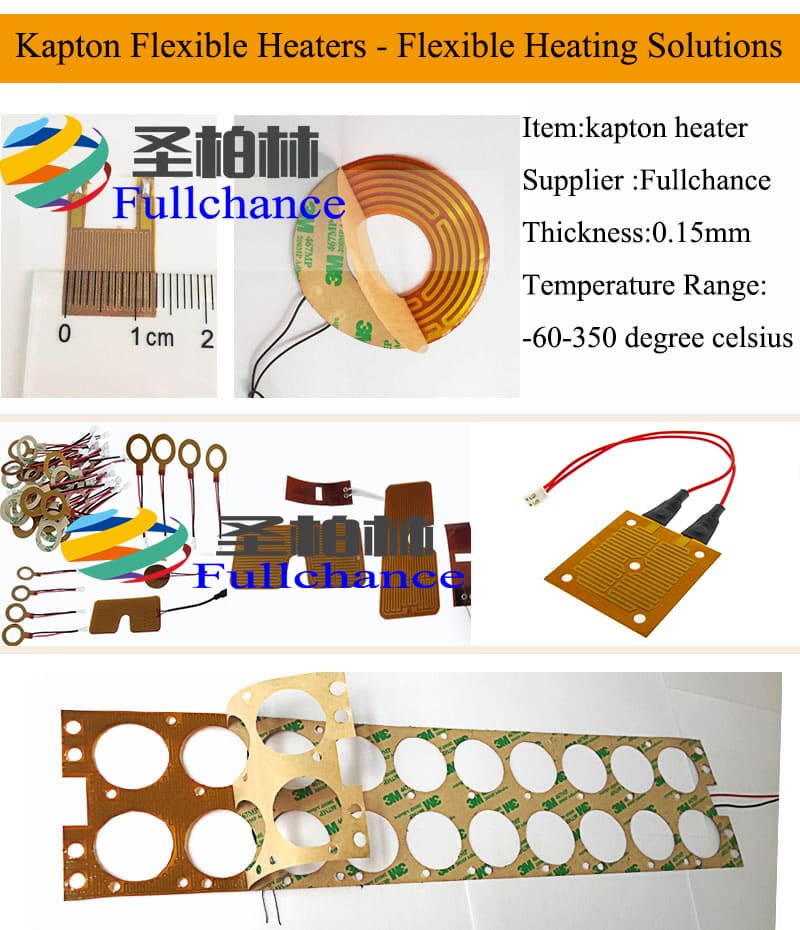

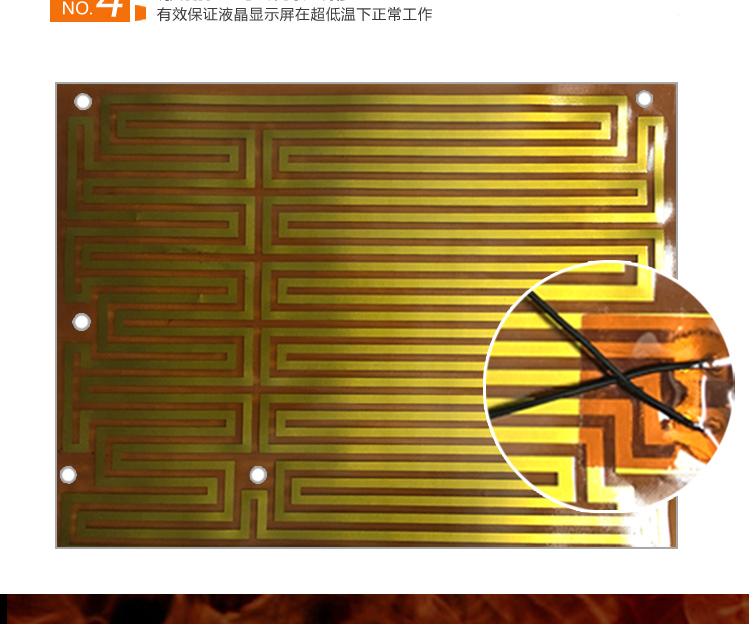

Wide Temperature Range

With an operating temperature range from -150F to +662F (-100C to +350C), polyimide Kapton heaters are suitable for use from extreme cold to extreme hot conditions.

![]()

Low Outgassing

Used in many vacuum and aerospace applications, polyimide heaters exhibit low outgassing of volatile materials under vacuum or at higher temperatures.

![]()

High Performance for Demanding Applications

The benefits of polyimide heaters are enjoyed by many industries

- Aerospace

- Electronics manufacturing

- Medical devices

- Semiconductor

- ...and more

-

-

-

-

Fullchance Surface Heating

Fullchance is a global leader in surface heating solutions with an unrivaled range of technical solutions to achieve the optimal solution. -

Foil Heating Solutions

Fullchance designs and creates customized heating solutions for your application or idea. Wherever heat is required, we will have the right heating solution. Our mission is to find an optimal, cost efficient solution for every customer with a need for heating elements. -

-

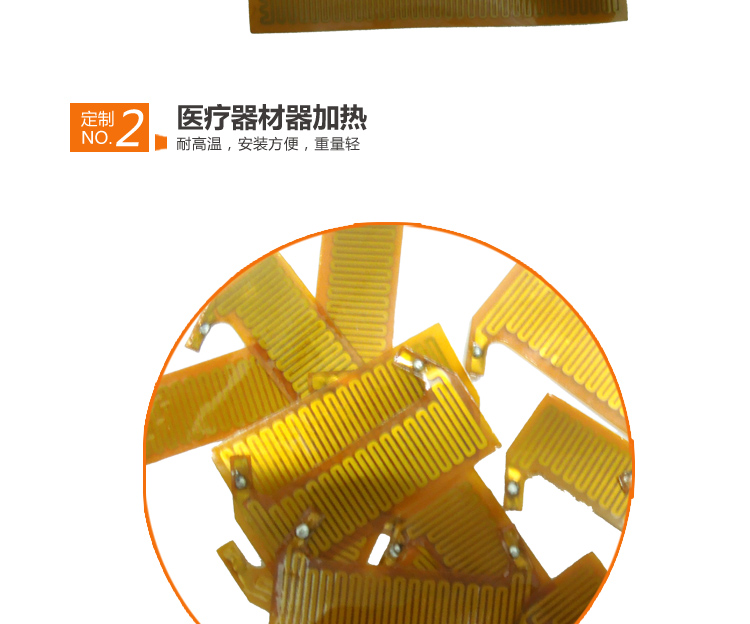

1.Medical equipment such as blood analyzers and test tube heaters

2.Computer peripherals such as laser printers

3.Curing of plastic laminates

4.Photo processing equipment

5.Semiconductor processing equipment

6.Thermal transfer equipment

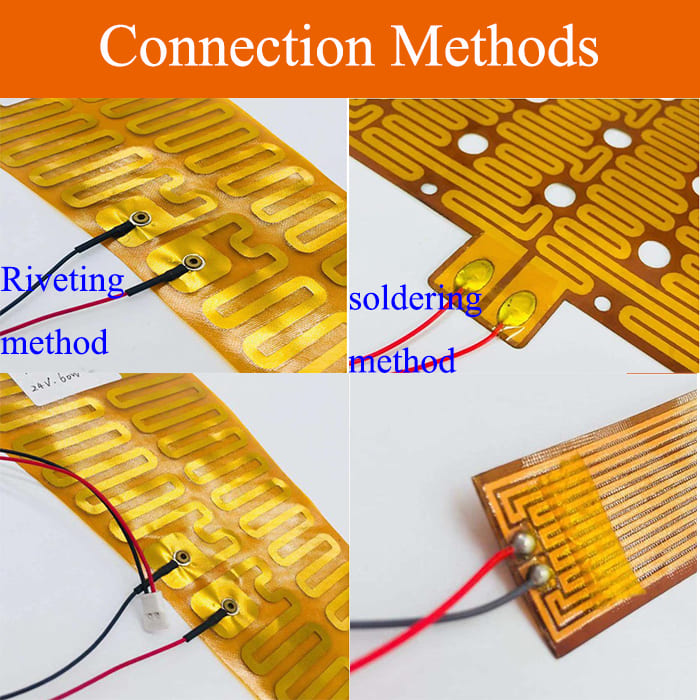

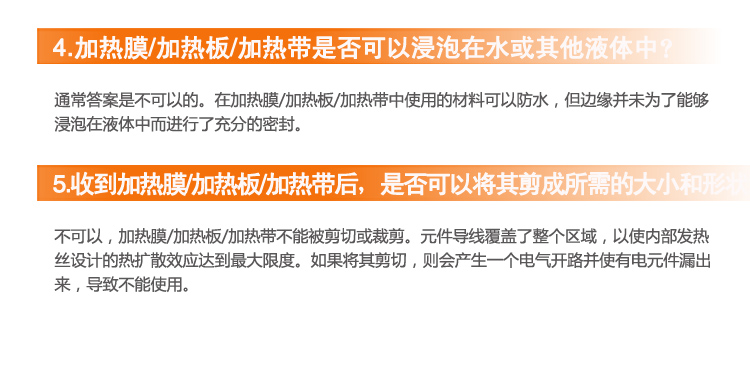

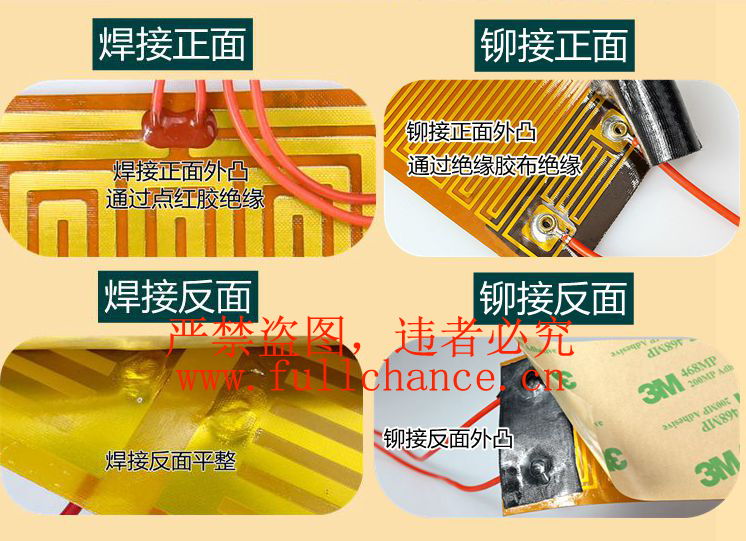

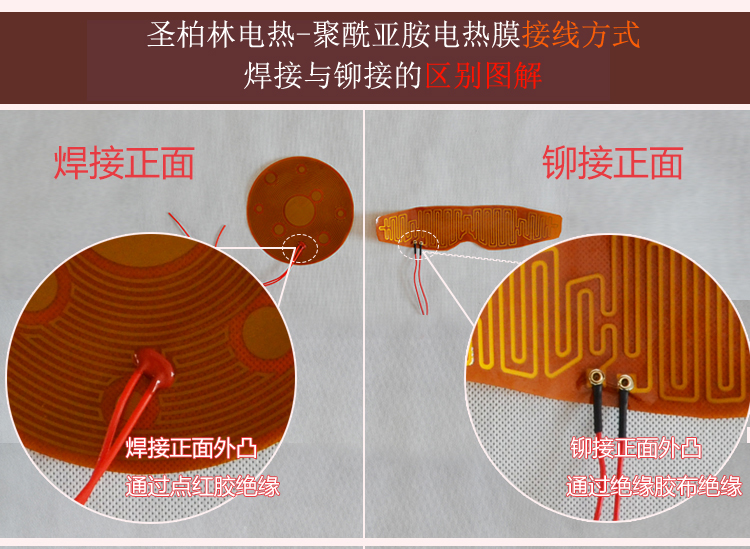

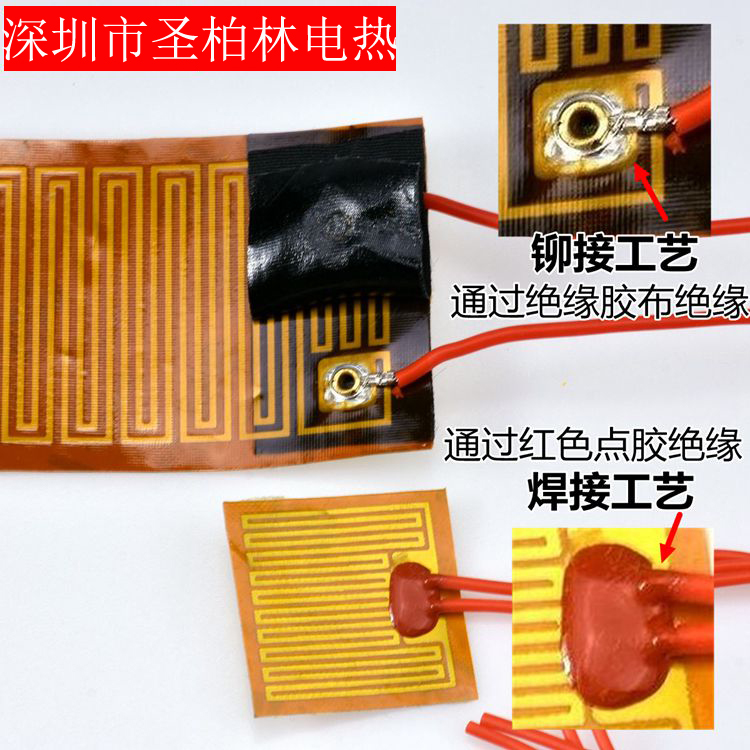

焊接与铆接图解对比

Kapton薄膜加热器、电热膜

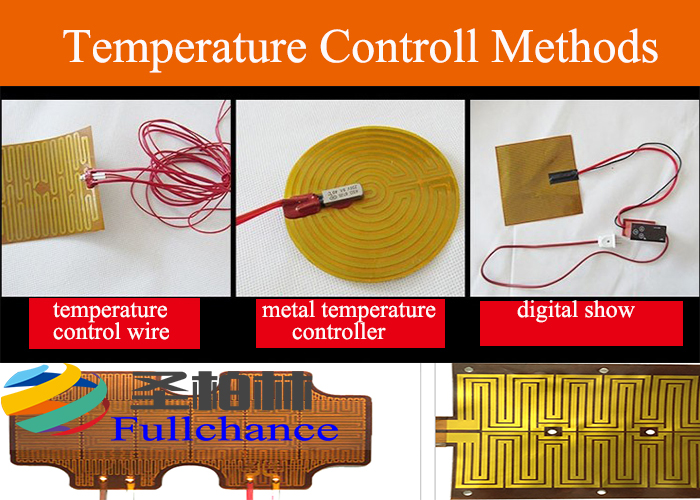

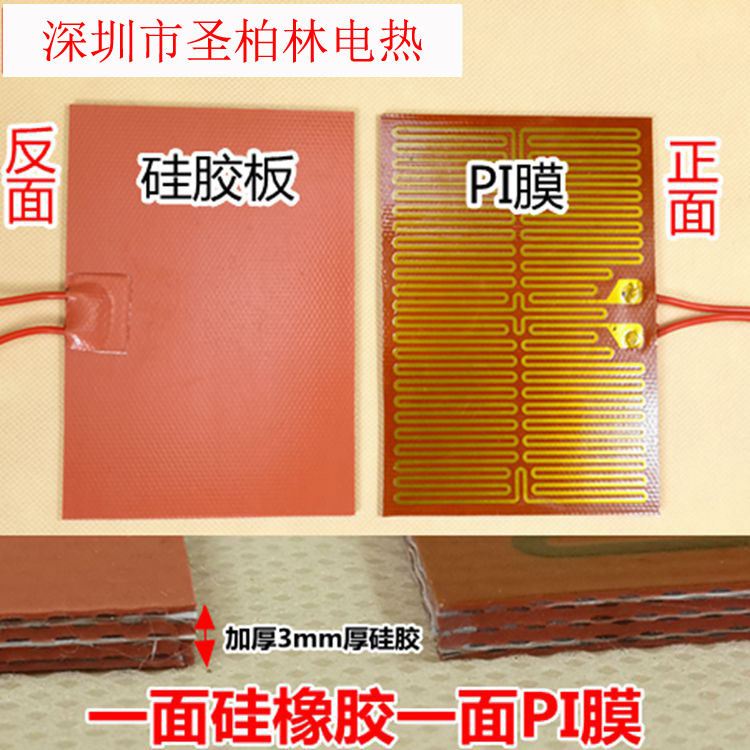

Fullchance’s Polyimide Flexible Heaters are your solution to heating curved and irregular surfaces. Due to their design, polyimide heaters can be extremely thin, as low as 0.007”, excluding any type of affixing adhesives. The etched circuit is pressed between 2-layers of polyimide film with either an FEP adhesive or an acrylic adhesive depending on the thermal characteristics required of the heater.

The design of a polyimide heater offers dimensional stability, superior tensile strength, and overall improved resilience. Polyimide is also resistant to most chemicals.

We offer multiple heating elements for polyimide heaters, such as stainless steel 304, CuNi44, and Inconel600, with excellent dielectric properties and operating environments between -319°F (-195°C) and 392°F (200°C). Kapton heaters also offer a quicker thermal transfer than silicone rubber heaters.

Benefits of Polyimide/Kapton® Flexible Heaters

Polyimide/Kapton® heaters offer several benefits for customers looking to utilize them in many different applications. Below are some benefits of using Polyimide/Kapton flex heaters in your application.

- Heaters have a lower temperature threshold than silicone rubber heaters, as they can operate within temperatures as low as -320°F and as high as 400°F.

- Polyimide has superior dielectric properties as they exhibit excellent tensile strength, durability, and dimensional stability which makes it almost impossible to tear even using the thinnest dielectrics.

- These heaters produce uniform thermal distribution which prevents uneven material expansions even with rapid heat-up and cool-down characteristics.

- Watt densities up to 50 W/in2 (7.75 W/cm2).

- Kapton® heaters can provide thermal stability over a wide temperature range and quicker response on thermal delivery to the surrounding mass.

- The resistive property is inherent to the film, so it cannot be cracked, rubbed off or otherwise easily damaged.

Heaters made on Polyimide/Kapton® material have low outgassing properties which means that the release of gas that was dissolved and trapped in the creating of the material is minimal. Outgassing can be a big problem if it collects in a closed environment where air moves slowly so the lower the emissions the better. Outgassed products can condense onto lenses and other sensors which is a problem if it collects in a closed environment.

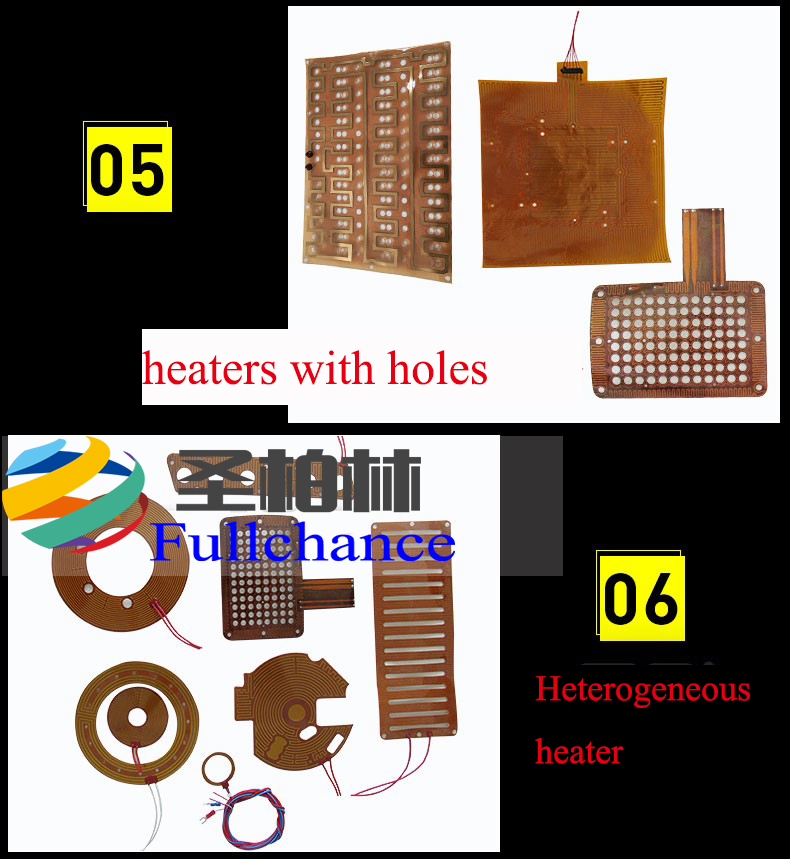

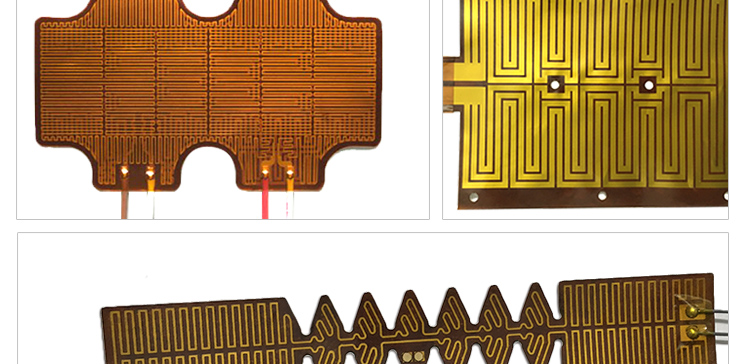

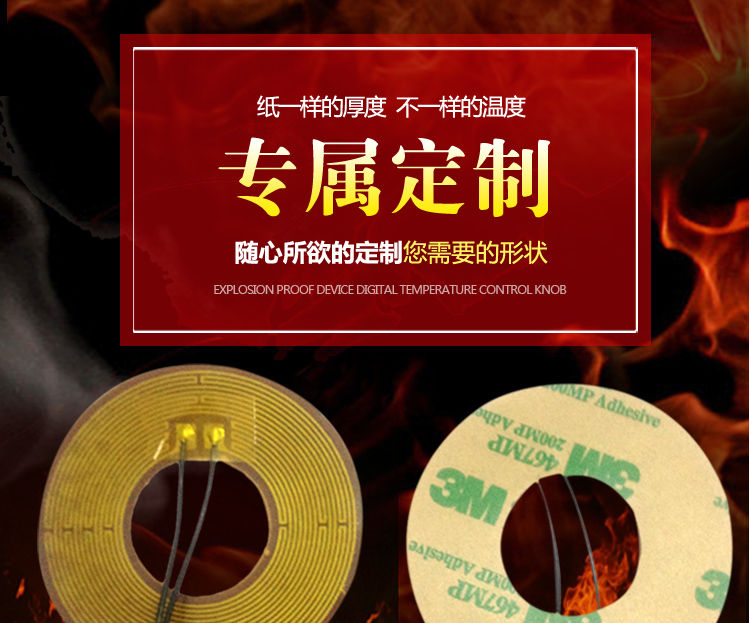

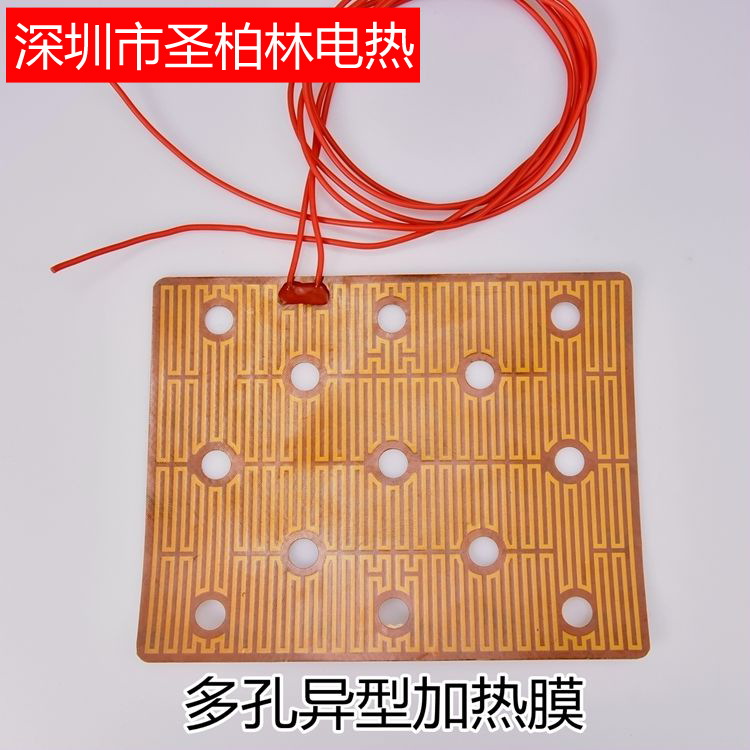

Custom Polyimide/Kapton® Flex Heater Solutions

Based upon the material to be heated (steel, aluminum, water, oil, plastic, air, etc.) custom designed and manufactured polyimide flexible heaters offer a low profile and rugged design while maintaining safety by being both abrasion and acid-resistant. Because we can create designs with any outline shape required, they are more cost effective and energy efficient than competitive solutions.

We utilize thermal imaging modeling based on your specs, that allow for design optimization as the image of the heater can be very precise as the photoimaging and chemical etching process can operate well within +/-0.003” tolerances. We have built our business on working with customers to design the perfect flexible heater for every application and are flexible enough to manage small quantities up to production volumes.

Features of a Custom Polyimide/Kapton® Flexible Heater Design:

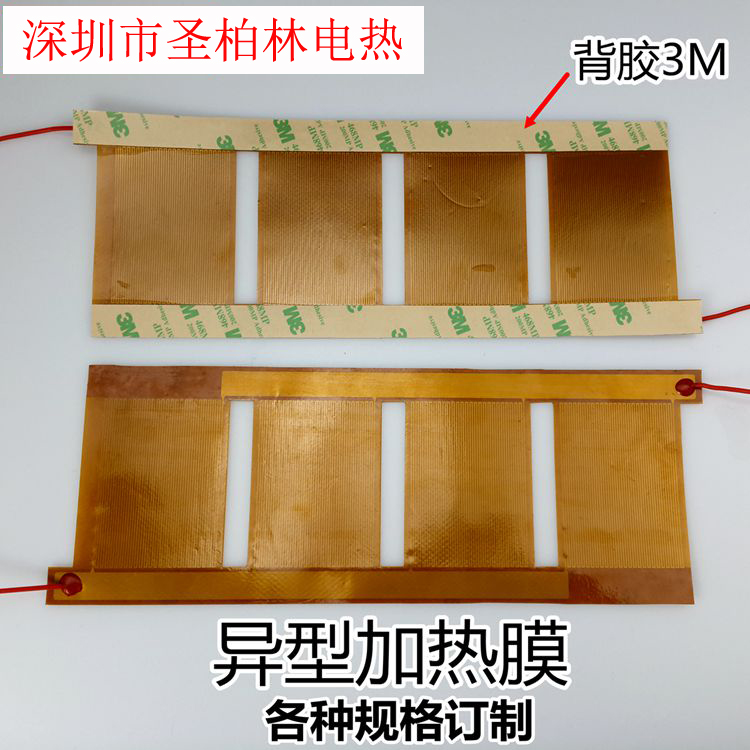

- Internal Cutouts

- +/-0.005” Using Mechanical Equipment

- +/-0.002” Using Laser Cutter

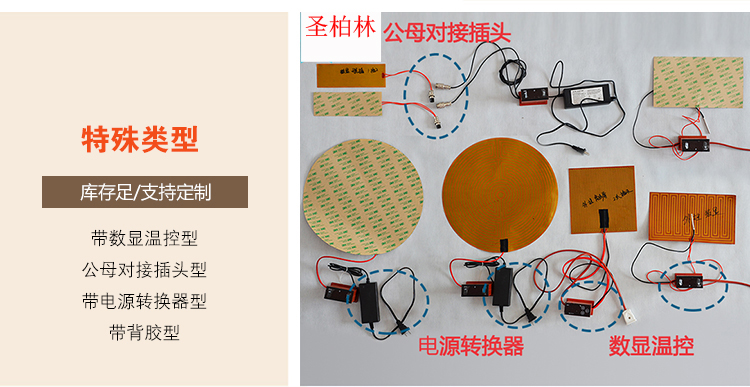

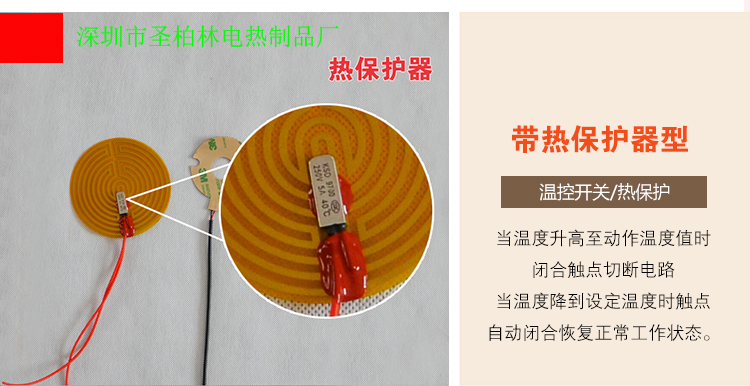

- Integrated Thermostats, Thermistors, Fuses and Other Components

- Mounting to Aluminum or Steel Supports

- Full Range of PSA’s (Pressure Sensitive Adhesives) To Meet Any Application

- Stiffeners for Connector Support

- Mounting Holes

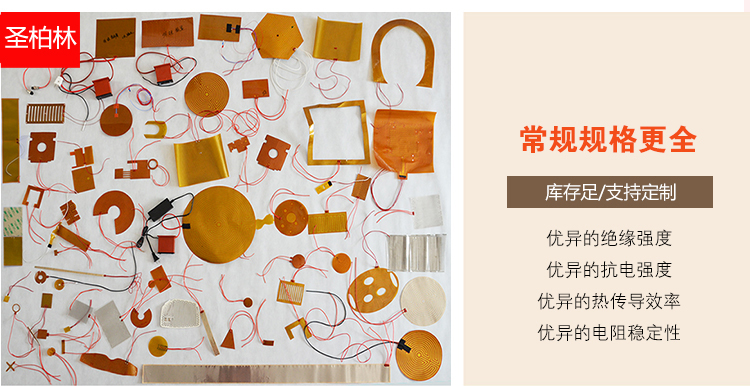

- Multizone Heaters

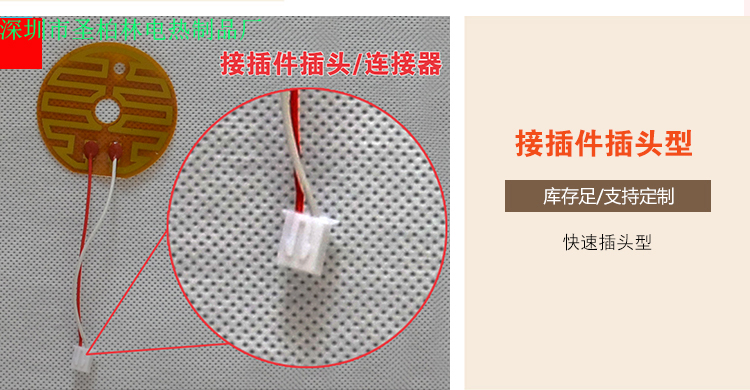

- Various Wire Lengths, Sizes and Connector Options

- Pre-Formed Flexible Heaters

- Strain Reliefs at Connection Point to Ensure Reliability

Fullchance Engineered Technologies only designs and manufactures custom Kapton®/polyimide flexible heaters

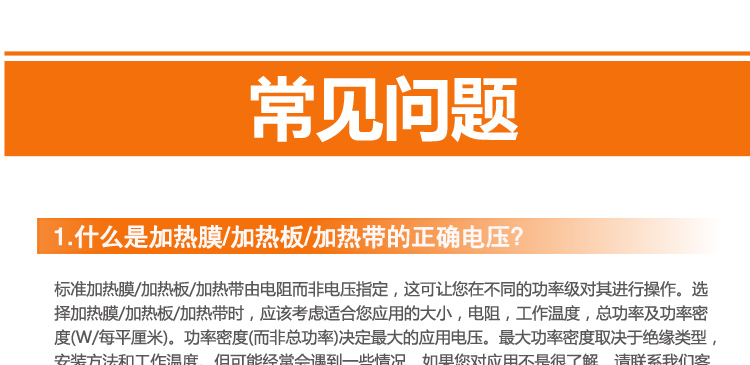

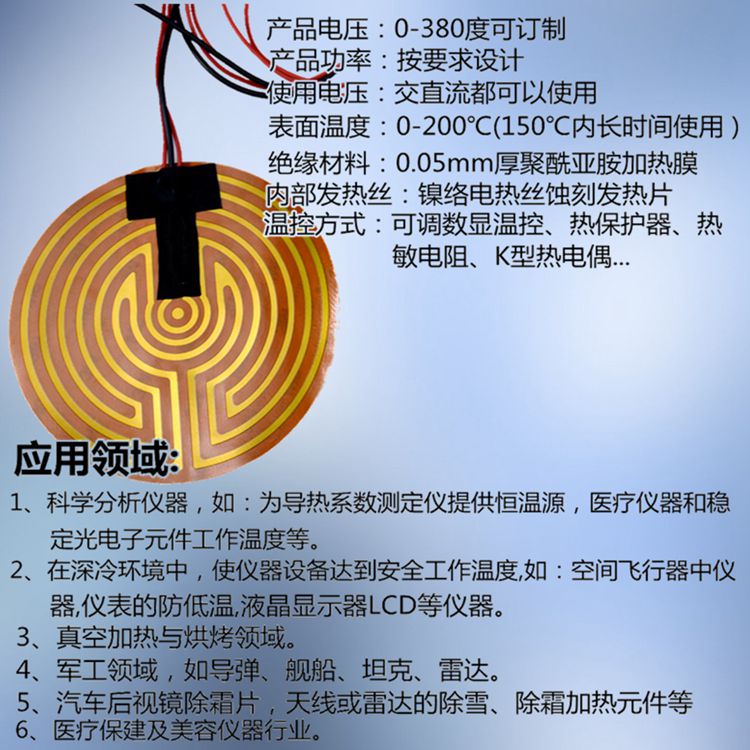

Current Specifications for Polyimide Heaters

- Maximum Watt Density: 50 W/in2

- Maximum Operating Temperature: 392°F (200°C)

- Minimum Operating Temperature: -319°F (-195°C)

- Wattage Tolerance: ±10%

- Dielectric Strength: 1000 VAC

Industry Benefits

Examples of industries that can benefit from the heating capabilities of a custom designed flexible polyimide heater include medical, aerospace, military, foodservice, and many more. Anywhere that operates with tight spaces and demanding conditions should consider the benefits of a Kapton heater.

customer service1

customer service1