INNOVATORS IN DESIGN & USE OF THICK FILM MATERIALS & PROCESSESFounded in 2010 by a group of Ceramic Engineers and Materials Scientists with backgrounds in microelectronic and hybrid manufacturing, ThickFilm Technologies provides Thick Film Design, Manufacturing and Consulting Services for Electronics Manufacturers, Design Engineers and Research Scientists.

THICKFILM TECHNOLOGIESBUSINESS MODEL

All design and production is made in the shenzhen of china  |

- Home

- Silicone Heater

Foam insulation silicone heater

Silicone heater with temperature controller

SILICONE RUBBER HEATERS – ACCESSORIES

Silicone Heater for Small Diameter Pipes and Tubing

special shaped silicone rubber heater

Different color silicone heater

Type W / Type E Silicone Rubber Heate

features&application of wire wound silicone heater

Standard silicon rubber heater

Silicone band Heater With Springs

Silicone Drum Heater With Velcro Straps

Silicone Drum Heater With Temperature Controller

Silicone Rubber Heater Temperature Controls

Useful information for designing silicone heaters

- Thick Film Heater

what are ceramic based thick film heaters,resistors,circuits of devices

Is thick film right for my applications

what base or substrate materials are available

what are the benefits of thick film heaters

which substrate materials should use?

what termination options are available?

what are the wattage densities of the thick film conduction heaters

waht if a standard thick film heater is close but not perfect for my applications

AVIATION LATCH HEATER(thick film on ceramic

2-ZONE HEATER FOR HANDHELD ANALYTIC DEVICE

DEVICE HEATING ELEMENT FOR USE IN A HIGHLY SENSITIVE MAGNETOMETER

- Polyester heater

- Epoxy Resin Heater

- Kapton heater

- Mica Heater

Mica HeaterUltra-thin・high Watt precision heater

High Frequency Round Mica Plate Heater Customized

High Temperature Surface Mica Heating Element

High Reliability Mica Heater Plate , Mica Electric Heaters Multi Function

The electric film mica heating element introduced

Mica Panel Heater/Heating Element

- Ceramic Heater

Alumina metallic ceramic heating element

Rectangular alumina metallic ceramic heating element specification

Round shape alumina metallic ceramic heating element specifications

Rod shape alumina metallic ceramic heating element specifications

4mm alumina ceramic porous wick for electronic cigarette

5W Ceramic Heater Element for Car Sensor 12V

MCH Printing Porous Ceramic Heating Element for Electric Cigarette

Electroniccigarette ceramic heater

Pellet System Applications Igniters

- Transparent Heater

Transparent Heater utilizes ITO technology

transparent heater custom&design

Transparent Heater with Nanofibrous Membranes

stretchable transparent heater

Clear Heater (ITO Heater), Anti-fog Heater, ITO film Heater, Film Heater, Transparent Heater

Clear Heater (ITO Heater for LCD display

Clear Heater (ITO Heater), Anti-fog Heater for TP 8 inch LCD display

ITO film Heater, Film Heater, Transparent Heater

- News

How to Install a Silicone Heater Build Plate

How a Silicone Heating Pad Works

Types of Flexible Silicone Rubber Heaters

Why Use Silicone rubber Heaters Over Other Heaters?

5 Advantages of silicone rubber heaters

Everything you ever wanted to know about Kapton heaters but were afraid to ask

what is ELECTRICALLY HEATED SILICONE BLANKETS

What Are Flexible Printed Heaters?

how to test kapton heater with Lithium Polymer (LiPo) battery

application of polyimide kapton heater

3D Printing Custom heaters for additive manufacturing and 3D printing

How do Polyimide Heaters Work?

What are the Operating Temperatures of Polyimide Heaters?

What are the Applications of a Polyimide Heater?

max working temperature of Polyimide Heater

How Does A Micathermic Space Heater Work Faster Than Regular Heaters

Are Mica Panel Heaters Safe and Effective?

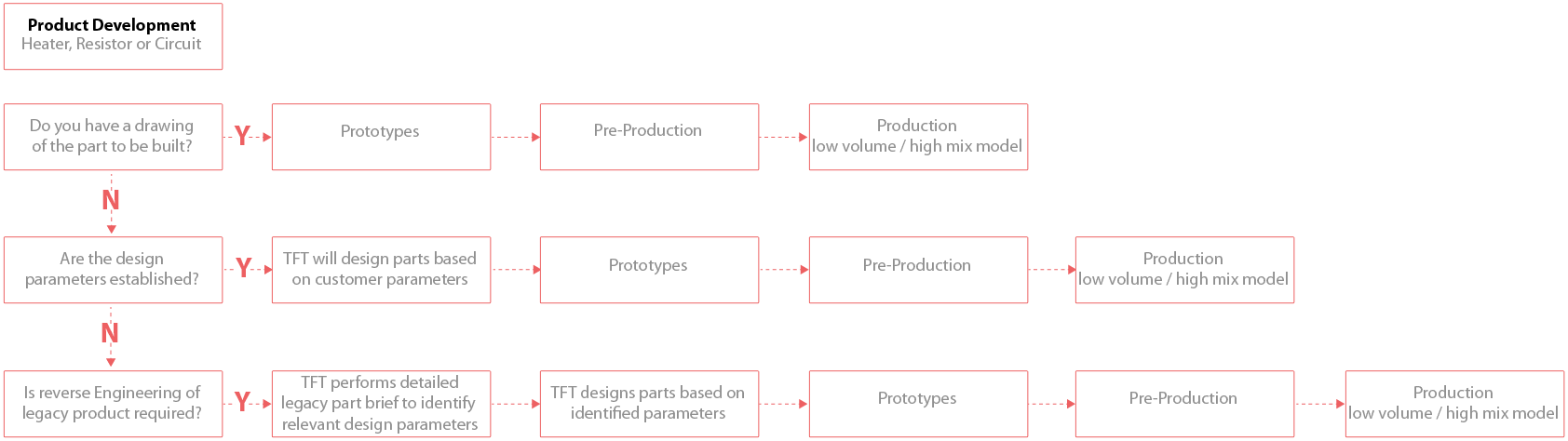

From consulting and design services to product manufacturing

Things to Consider When Specifying a Heating Application

Kapton Flexible Heaters - Flexible Heating Solutions

Thick film elements - Technical data

How do I estimate battery run-time for my heated device?

Understanding Watt Density in Heater Design

latest product-230V 1.2W 50000ohms carbon heater

what is etched-foil kapton heaters

ITO conductive glass and related transparent conductive films

- Data Download

Fullchance FILM HEATERTEST WITH SINK

Electric heating film product catalog

Ceramic electric heating tube product catalog

ITO conductive glass and related transparent conductive films

Transparent electric heating film video

PI High Temperature Electric Heating Plate Test Video 300 degrees

Transparent electric heating film inspection report

General testing standard for mica electric heating plates

Hot stamping machine, baking cup heating pad information download

Electric Heating Production Operation Instructions

Electric heating film, flexible heating film test report

Operating Procedures for Electric Heating Plate Production

Analysis of Electric Heating Plate Mechanism

Test Report on Kapton (PI) Insulation Layer for Electronic Cigarette

Temperature Uniformity Test Video for Epoxy Resin Electric Heating Plate

Production process and process flowchart of electric heating film

Instructions for Inspection of Mica Heating Plate

Technical description of ITO transparent electric heating pads for ski goggles and helmets

- Company Profile

- Factory Equipment

Electric heating film application - medical diagnostic equipment

Electric Heating Film Application - Aviation

Application of Electric Heating Film - National Defense

Electric Heating Film Application - Engineering Automation

Electric heating film application - power generation

Electric Heating Film Application - Rotating Machinery

Electric heating film application - semiconductor manufacturing

Electric Heating Film Applications - Industrial&Commercial Applications

Installation drawing of CT325 temperature controller

CT435 Temperature Control Installation Drawing

Installation Drawing of CT425 PID Temperature Control System

- Contact Us

customer service1

customer service1